Overview

Critical spare parts for an Ingersoll-Rand reciprocating air compressor (60–125 HP) supplied to NISOC. The project required alternative sourcing and rigorous quality documentation under international procurement constraints.

Context

NISOC issued an RFQ for critical compressor spares. Downtime risk was significant and documentation had to meet MESC and QA/QC requirements.

Challenge

- Initial vendor withdrew after technical approval

- Tight delivery timeline (≤150 working days)

- Full compliance package required (certificates, test docs)

- Market and sourcing limitations increased complexity

Our Approach

- Rapid re-sourcing via qualified suppliers

- Negotiation and securing compliant replacements

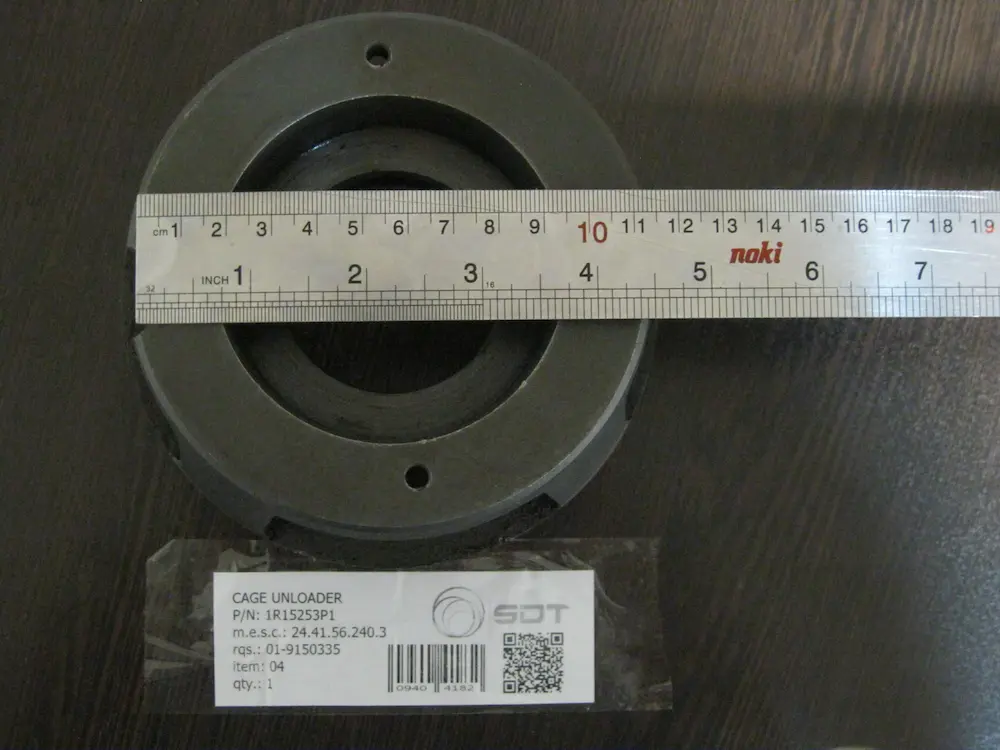

- QA/QC checks, dimensional verification, documentation

- Managed packaging, labeling, traceability and logistics

Outcome

- Full delivery within contractual timeframe

- Complete documentation package

- Successful client acceptance by NISOC

- Demonstrated Nexa’s capability in critical sourcing

Note: Executed under the leadership of Nexa’s founder during his tenure at Sperloos Delta Tejarat (2015)